How are hand-forged knives made? Inside Leaping Dog Forge

We've all admired knives hand-forged by a master of the craft. We've all oohed and aahed at the sleek Damascus blade and the polished, hand-crafted handle. But exactly how are hand-forged knives made? And what's so special about such a small thing anyway...after all, it's just sharp steel with a handle, right? Here, we walk you through our process of forging a knife step by step.

STEP ONE: Choosing the Steel Billet for a Hand Forged Knife

Knives at Leaping Dog Forge begin as a blank piece of high carbon steel. It could be a billet created specifically for forging, it could be a railroad spike, or even a piece of spring from an old car. If the billet is a raw piece of steel, then the blacksmith will immediately proceed to step two. However, if the smith is working with repurposed steel, impurities in the metal can lead to flaws in the integrity of the knife later on, so it first must be cleaned. This is done by going over the repurposed metal with a wire wheel or brush.

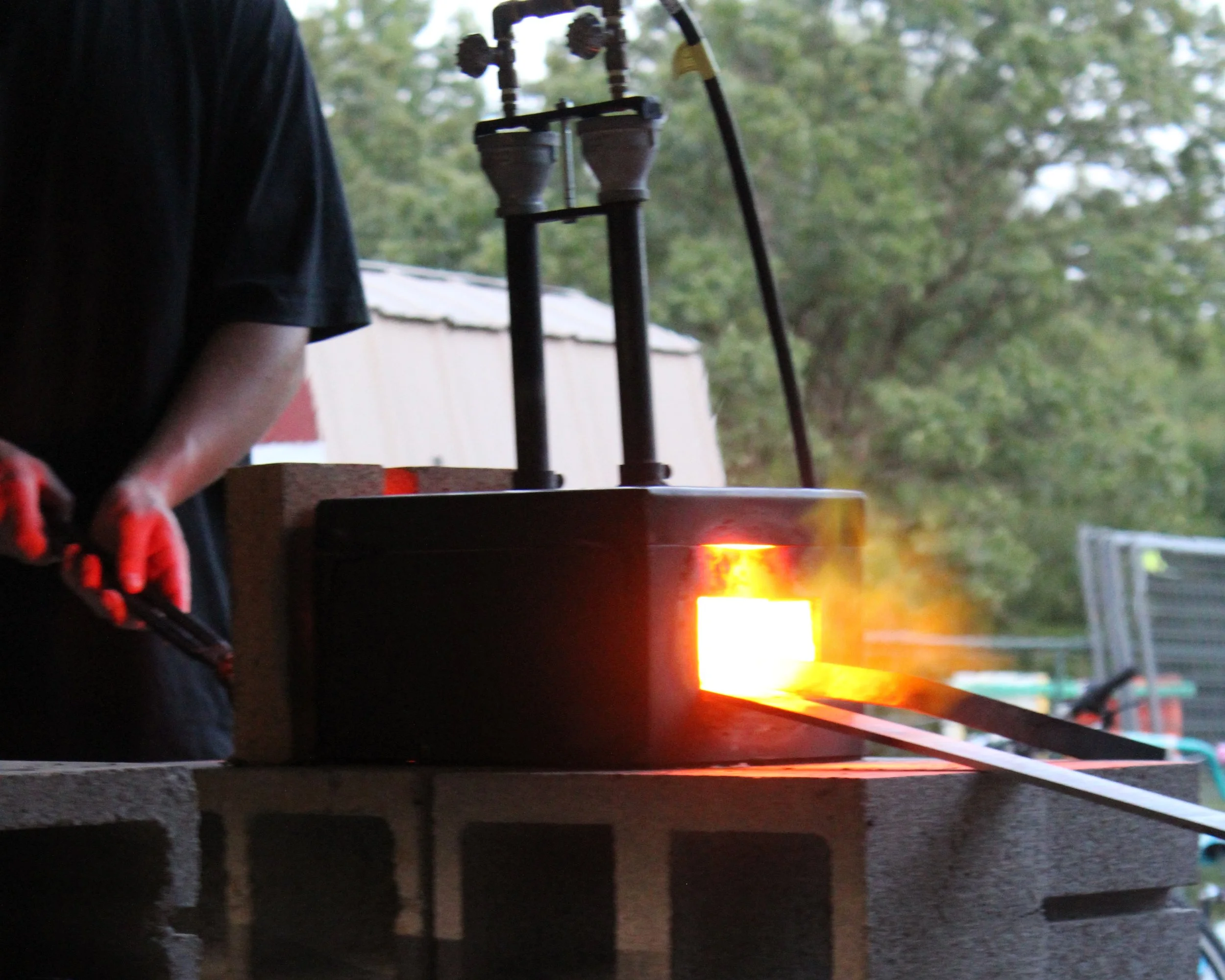

Steel billets heating in the forge.

STEP TWO: Heat and Hammer: Forging the Knife Blade by Hand

This is the part of the blacksmith knife making process that everyone is familiar with. Billets are placed in the forge and left untouched until they reach a bright, glowing orange. Then they are removed using tongs to transfer the metal to the anvil, and struck repeatedly with a hammer, shaping the billet into something that begins to resemble a knife. Once the metal cools enough so that it is no longer malleable, it is placed back in the forge. This process is repeated as many times as necessary for the knife to reach the desired shape.

A blacksmith hammers out the tang of a knife.

STEP THREE: Grinding and Sharpening the Forged Knife Blade

While the knife is technically shaped the way it should be, it is currently dull and covered in scale. The scale can be removed through wire-wheeling, but to sharpen it will require a grinder. The edge will be sharpened and the rest of the blade ground until the smith likes the way it looks.

STEP FOUR: Quenching a Forged Knife to Harden the Steel

The structure of the metal has been softened by the forging process, which is no good for knives. Now it needs to be hardened again. The knife is placed in the forge for one last heat; once it reaches the desired color, it will quickly be removed and submerged in oil for a few seconds. The knife is then placed in a bucket of sand to allow it to cool completely. A successful quench will harden a blade without altering its shape or integrity, but if done wrong, the knife can come out of the oil warped or cracked.

STEP FIVE: Tempering a Hand Forged Knife for Strength and Flexibility

The knife has been softened during forging and then hardened during the quench. The problem is that now the knife is brittle, which is also a problem. To fix this, the knife is placed in an oven at 400 degrees F for two hours, taken out of the oven for one hour, and placed back in the oven for another two hours. Then the knives are allowed to cool to room temperature. After heat treating (which is the term for the process from quenching to tempering), the knife is hard enough and flexible enough to take a blow without breaking or bending. Once the blade is finished, it will be wrapped to safeguard against damaging it or anyone’s hands while the handle is attached.

STEP SIX: Preparing and Stabilizing Wood for Knife Handles

As if there weren't enough steps to go through with the metal part of the knife, you also have to stabilize the wood used for the handle! Unfortunately, the thing that used to be alive has pores, and those pores are filled with air, which isn't good for some reason. To fix this, the wood is placed in an oven at 220 degrees F and removed at regular intervals to be weighed. The wood is done when it stops losing weight: this can take up to 24 hours. It is then placed in a vacuum chamber with this expensive stuff called cactus juice (no, I don't think it is made from cactus). The cactus juice—which is a resin—permeates all of the wood’s pores and fills them up so that all of the air in the pores is displaced. Somehow this makes the wood stronger. Don't ask how, we're blacksmiths—not scientists! As with billets, stabilized wood blocks can be purchased online, but why do things the easy way?

STEP SEVEN: Attaching the Handle to a Forged Knife Tang

This is where creativity and careful planning meet. There are many ways of attaching a handle to a knife's tang. Among them are sandwiching the tang between two pieces of stabilized wood and securing them with pins. You could also carve a space between two scales to fit over the tang and secure it with pins or epoxy. Another option is a burn-in. A burn-in means you take a blowtorch, heat up the tang, and then press the red-hot tang into a wooden block so that, theoretically, the tang burns itself perfectly into the handle. This can be difficult if you rush things. Some knives have a guard between the handle and the blade, which will be shaped and attached in this phase.

STEP EIGHT: Shaping and Finishing a Knife Handle

This step is fairly straightforward. The knife handle is shaped using a belt grinder or angle grinder and sanded. Any ornamentation of the handle, such as wraps or inlays, is done here.

An example of hollow pins holding together a knife handle.

STEP NINE: Final Finishing, Sharpening, and Blade Protection

All knives at Leaping Dog Forge have had the blades hand-sanded and sharpened, and rubbed with wax to prevent rust. This process can take up to twelve hours total, depending on the desired finish.

WHY DOES THIS MATTER?

The craft of blacksmithing has been passed down for centuries. Each one of our finished knives takes 15-120 hours of active labor to complete, not to mention all of the hours dedicated to learning how to make them! By supporting blacksmiths, you are helping to preserve a craft that would otherwise be lost to history.

If preserving how hand forged knives are made isn’t what floats your boat, then consider that everything hand-forged, from our hooks to our knives, is unique because it is practically impossible to create anything identical by hand. Buying hand forged is a guarantee that what you have is 100% unique.

People Also Ask…

-

Depending on the complexity of the knife it takes 15-120 hours to get from the billet to the finished knife.

-

Hand forged knives are taken from billets to finished knives using traditional knife making techniques. Factory made knives are stamped or cut from a sheet of metal. Read more here.

-

Damascus knives are created by layering at least 2 different steel alloys through forge welding them together (canasters are a different story). The steel is then folded and or twisted multiple times to create layers and patterns which will be visible in the finished knife. The combining of multiple steel alloys adds to its visual appeal.